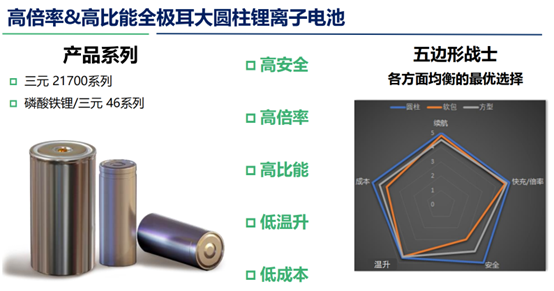

Domestically produced high-rate & high-energy-density tables large cylindrical lithium-ion batteries are set for mass production, with Phase 1 of the project targeting an annual capacity of 14-16GWh.

Urgent Demand: The World Is Waiting

Unlike the cutthroat competition in China’s new energy vehicle sector, the global high-end markets for power tools and small-scale ESS (energy storage systems) remain dominated by Japanese and South Korean players. High-rate & high-energy-density tables large cylindrical lithium batteries, in particular, are in desperate demand worldwide.

Why the Rush?

Current lithium batteries are insufficient: 85% of garden tools still rely on fuel, heavy-duty impact tools require wired power, and electric forklifts/OPE (Outdoor Power Equipment) spend half their runtime charging. According to the China Power Tool Industry Development White Paper, global demand for lithium batteries in power tools is projected to exceed 4 billion units by 2026.

For high-performance tools, batteries are overwhelmingly sourced from Japanese and South Korean brands. These advanced lithium batteries, requiring cutting-edge technology and ultra-strict manufacturing processes, have long been a challenge for Chinese firms to produce at scale, leaving global top-tier tool manufacturers underserved.

With Reliance Energy’s successful R&D and mass production of its 21-series high-rate & high-energy-density tables large cylindrical batteries, China has shattered this bottleneck.

Data reveals Reliance Energy’stabless large cylindrical batteries far surpass conventional designs:

• 70% reduction in internal resistance vs. conventional tab structures.

• 30% lower operating temperature rise during high-rate discharge.

• 80% higher lifecycle energy output compared to conventional tab cells.

A single-parallel 21700 cell can replace dual-parallel 18650 cells while matching energy/power output. For instance, a 4.0Ah 21700 battery pack fully substitutes a dual-parallel 2.0Ah pack, slashing weight and volume by 30% and lowering PACK costs.

In extreme testing, the battery achieves:

• Continuous discharge over 100A for instantaneous high-power tools.

• ≥3C fast charging with ultra-low impedance, maintaining cycle life.

• 10-minute “super-fast charge” from 0% to 80% capacity.

Mass Production & Partnerships

Reliance Energy’s Phase 1 capacity will reach 14-16GWh annually, producing 500-600 million cells. The company has secured partnerships with leading global tool manufacturers. Dartek, China’s top lithium-powered tool maker, has developed a premium product line using Reliance Energy’s batteries, with tables models set to launch in Q2 2024.

Patience: Doing the hard but right things

“China’s high-rate & high-energy-density tables batteries have surpassed expectations!” exclaimed Mo Ke, founder of ZhenLi Research. He hailed Reliance Energy’s two-year journey from R&D to mass production—prioritizing quality over China’s legacy of “quantity over refinement”—as a “miracle.” But behind the scenes, this “miracle” stems from Reliance Energy’s core team’s relentless focus and decades of technical grit.

Chen Xuan, Reliance Energy’s founder and CEO—a 20+ year veteran of high-end manufacturing and lithium battery innovation—embodies this philosophy. At an internal strategy meeting, she declared: “Life offers two choices: endure hardship first for later rewards, or seek ease first and suffer later. For products, either make batteries the hard way or struggle to sell them. We choose the former.”

From its 2022 launch in Changzhou to pilot production in 2023 and customer testing in 2024, Reliance Energy has remained laser-focused on its mission, resisting distractions from the booming EV battery market.

Reliance Energy’s goal is clear: Develop China’s professional/industrial-grade lithium batteries, rival global leaders, and become the world’s premier supplier of compact power and portable energy storage solutions.

Three Pillars of Success

Market Assurance: Only a handful of firms globally can mass-produce these high-spec batteries.

Patient Capital & Team: Investors and a seasoned team of serial entrepreneurs prioritize precision over quick profits.

Elite Talent: Reliance Energy’s R&D team—drawn from top global institutions and lithium giants—boasts 10+ years of technical leadership, amplified by collaboration with Japanese engineering experts averaging 15+ years of lithium experience.

World-Class Infrastructure

Backed by cutting-edge production equipment, digital systems, and a ZTE-powered smart factory, Reliance Energy ensures unparalleled consistency and efficiency.

Conclusion

Reliance Energy’s meteoric rise stems from Chen Xuan and her team’s decade of industry mastery. By uniting China’s finest investors, engineers, and client insights, Reliance Energy has forged a lithium revolution—and a guarantee of world-class performance.